Engineering & Fabrication Services

GMAW, SMAW, FCAW and GTAW welding (stainless and aluminium TIG and PULSE mig)

CNC plasma and flame profiling (25mm pierce, 50mm edge start*) and engraving

Punching

Shearing/Cropping

Drilling and Taping

Pipe bending up 70mm OD and 50mm SHS (see Table for available profiles)

Pipe threading up to 4”

Section rolling (pipe, tube, flat bar and SHS/RHS)

General Turning

Design and Drafting (3D cad and drawing)

3D scanning/printing

3.0t, 3.5t and 16T forklifts

135T NC Press brake

10T overhead crane

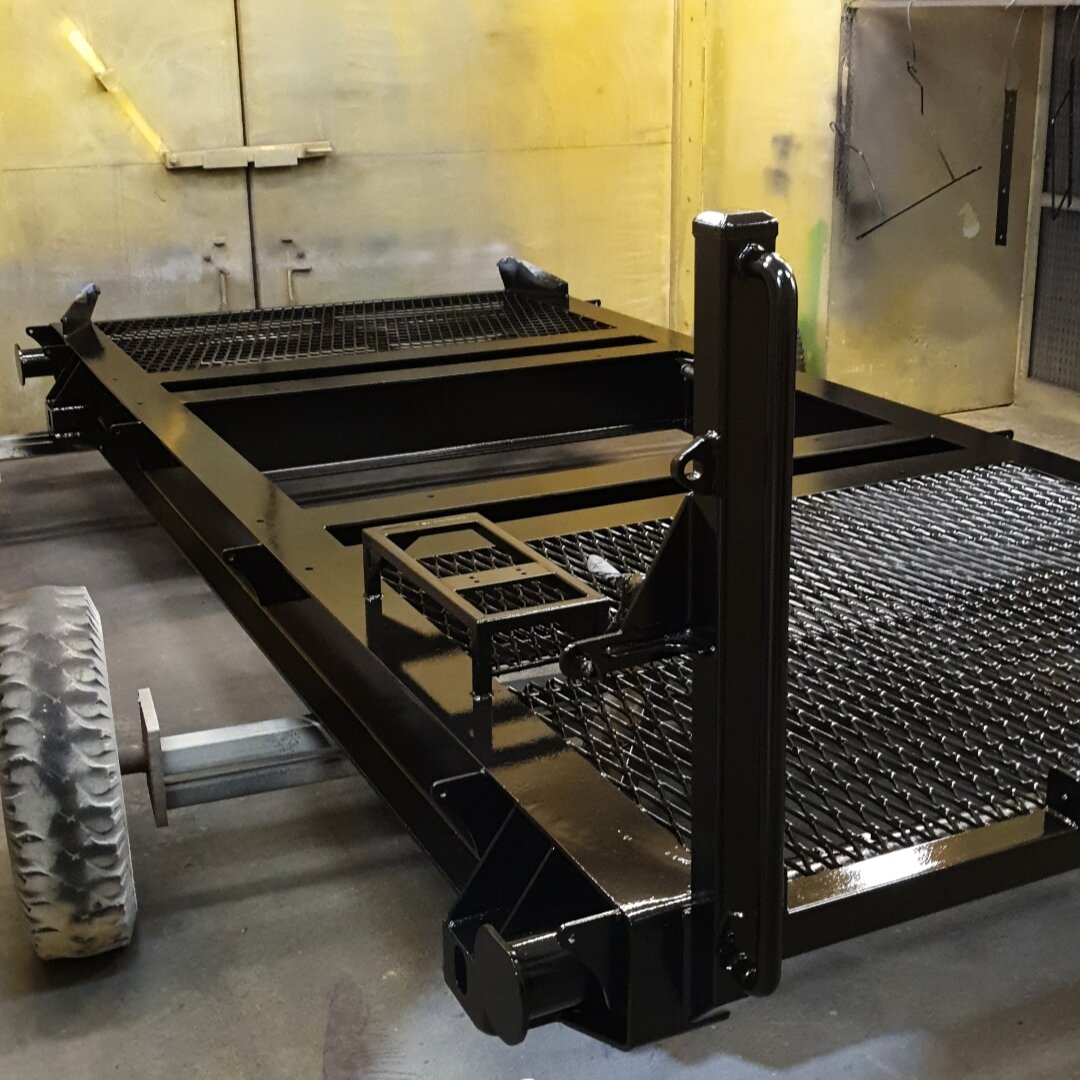

Abrasive Blasting & Industrial Coating

Barco Industrial provides professional painting and abrasive blasting services designed to protect and enhance every product. Our abrasive blasting process ensures surfaces are meticulously prepared, removing impurities for optimal coating adhesion. We can then apply high-quality, durable paint finishes tailored to withstand tough conditions, enhancing both the appearance and longevity of your equipment and products.

We can work to your specified coating system or recommend a proven system that meets your projects requirements.

We also apply a range of polyurethane bed liners and rubberised protective coatings for high-wear areas and impact-prone equipment.

Decal removal and replacement services are also available.

-CAD/Product Development

-3D scanning/Printing

At Barco Industrial, we offer specialized CAD and product development services using SolidWorks to create precise, functional models.

Our team works from initial concept through to final design, ensuring that every model is tailored to meet unique project requirements.

With SolidWorks’ advanced capabilities, we deliver high-quality, manufacturable designs that streamline the journey from concept to production.

We can 3D scan parts to create accurate digital models, then reverse engineer them for repairs, replacements, or upgrades. Ideal for worn, discontinued, or custom components.